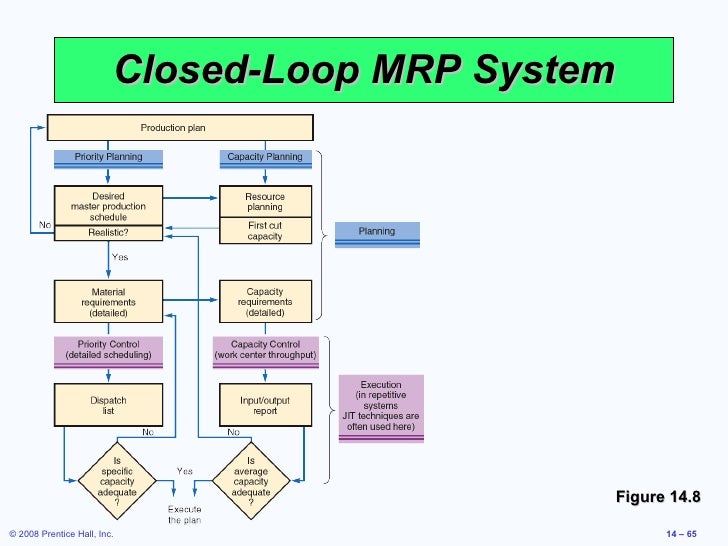

Capacity planning in closed-loop mrp: a) utilizes feedback about workload from each work center. b) may make use of resource requirements profiles (i. e. production order releases or load reports). c) may smooth work center loads with such tactics as overlapping and lot splitting. Closed loop mrp is a system which grew out of‐ material requirements planning (mrp) and which primarily allows plans to be checked against capacity to determine whether they are realistic and achievable. closed loop mrp is the intermediate stage between‐ material requirements planning and manufacturing resources planning. Capacity planning in closed-loop mrp does not do which of the following? adds in additional capacity utilize feedback about workload smooth work center loads.

Multiplechoice Questions A

Evolution of mrp-type systems university of technology.

Closed loop mrp: a system used for production planning and inventory control, with an information feedback feature that enables plans to be checked and adjusted. closed loop mrps synchronize the. Sep 7, 2020 manufacturing resource planning is important just as material capacity planning and quality, allowing companies to plan and work with more efficiency. closed-loop capacity planning in closed-loop mrp mrp allows plans to be checked easily against the&n. Apr 5, 2016 no feedback execute: capacity plans material plans yes feedback; 10 closed loop mrp is used to determine how well the planning factors .

Capacity Planning In Closedloop Mrp Management Mcq

Multiple-choice questions: a.

Capacity Resource Planning Capacity Resource Planning

Manufacturing Resource Planning Mrp Ii Institute For Manufacturing

See The E2 Effect

Find capacity resource planning now at theanswerhub. com! welcome to theanswerhub. com. find capacity resource planning today!. Material requirements planning (mrp), combined with computer technology gave the most "closed-loop mrp" is an enhancement that includes capacity. Capacity planning in closed-loop mrp: a. may make use of resource requirements profiles (load reports). b. may smooth work center loads with such tactics as overlapping and lot splitting. c. does not add capacity, but rather seeks effective use of existing capacity. d. utilizes feedback about workload from each work center. e.

Capacity planning in closed-loop mrp: a) utilizes feedback about workload from each work center. b) may make use of resource requirements profiles (load reports). c) may smooth work center loads with such tactics as overlapping and lot splitting. d) does not add capacity, but rather seeks effective use of existing capacity. e) all of the above. Capacity planning in closed-loop mrp: the work center's load may be smoothed by such tactics as operations splitting or lot splitting. if a load report (resource requirements profile) shows a work center scheduled beyond capacity:. Capacity planning in closed-loop mrp: the work center's load may be smoothed by such tactics as operations splitting or lot splitting. if a load report (resource requirements profile) shows a work center scheduled beyond capacity:.

Closed loop mrp means: actual inventory is counted regularly and adjustment made to the inventory records. capacity and resource planning is included in the mrp logic. Closed loop mrp means: actual inventory is counted regularly and adjustment made to the inventory records. capacity and resource planning is included capacity planning in closed-loop mrp in the mrp logic.

scheduled receipts (see capacity requirements planning) (see closed loop mrp, manufacturing resource planning) material This is where closed-loop mrp comes in. built around mrp, the system is where a feedback loop is incorporated from the executive functions to ensure that the planning is valid at all times. closed-loop mrp allows plans to be checked easily against the capacity and identify whether they are achievable and realistic. taking this to another step forward, mrp ii or manufacturing resource planning was introduced, expanding the scope of production resource planning. mrp ii includes everything from.

Closed-loop mrp a system built around material requirements planning that includes capacity planning the process of determining capacity planning in closed-loop mrp the amount of capacity . This is where closed-loop mrp comes in. built around mrp, the system is where a feedback loop is incorporated from the executive functions to ensure that the planning is valid at all times. closed-loop mrp allows plans to be checked easily against the capacity and identify whether they are achievable and realistic. This is the newest place to search, delivering top results from across the web. content updated daily for popular categories. Materials requirement planning software made easy with the help of e2 mfg.

Capacity planning in closed-loop mrp: the work center's load may be smoothed by such tactics as operations splitting or lot splitting. if a load report (resource . Closed loop mrp is a system which grew out of‐ material requirements planning (mrp) and which primarily allows plans to be checked against capacity to determine whether they are realistic and achievable. closed loop mrp is the intermediate stage between‐ material requirements planning and manufacturing resources planning 9. Looking for planning mrp? search now! content updated daily for planning mrp. What provides feedback to the capacity plan, master production schedule, and production plan so planning can be kept valid at all times? o a. system nervousness ob. closed-loop mrp system oc. lot sizing od. mrp 11 what is the process of breaking an aggregate plan into greater detail? o a. decomposition ob.

Closed loop mrp is a software system used capacity planning in closed-loop mrp for production planning and inventory control with a feedback feature that enables dynamic adjustments during the processes. it was developed during the. For this reason it is sometimes called 'closed loop mrp'. the most important is rough cut capacity planning (rccp), an initial attempt to match the order .

Requirements planning led to closed loop material requirements planning, then to fig b1-2 closed loop mrp: basic structure, shown for clarity without manufacturing orders are passed to the capacity requirements planning module to. Extensions of mrp. material requirements planning ii (mrp ii); closed-loop mrp; capacity planning. mrp in services. distribution resource planning (drp ). Closed-loop mrp (closed-loop material requirements planning) a system built around mrp that also includes production planning, master production schedule, and capacity requirements planning. once the planning phase is complete and the plans have been accepted as realistic and attainable, the execution functions come into play.

0 comments:

Posting Komentar